Description

Free shipping in Canada for orders over $140 before tax. (via Canada Post)

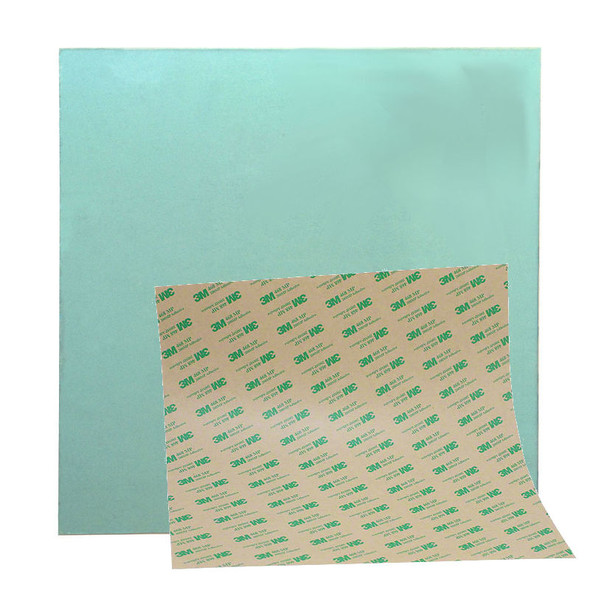

PEI (polyetherimide) is a strong, rigid plastic that withstands high temperatures and is readily available in transparent to amber colour. It is an ideal build surface for FFF 3D printers. This sheet comes with our 3M 468MP adhesive sheets pre-applied. When heated, the PEI sheet grabs onto your 3D print and doesn't let go, negating the need for a print raft. After printing, allow the sheet to cool before removing your 3D print - print easily detaches once the sheet is cooled to room temperature. This is a multiple use, no-mess product.

If adhesion is lost, please try washing with dish soap and hot water, dry thoroughly and wipe with isopropyl alcohol. Sanding the PEI sheet with fine grit sandpaper and wiping with isopropyl alcohol can clean and improve adhesion.

Key Features:

- 0.15mm/8mil thickness - no protective film, 3M 468MP double sided adhesive pre-applied

- Works with ABS, PLA, HIPS, PET+, Brick, Wood & Flexible (TPE/TPU) filaments

- Installs much easier than masking tape or films typically used

- Protects build plate

- Heat resistant and durable, can be reused for many consecutive builds and you can use different filament materials without the need to change the printing surface

- Creates an optimal bond between the 3D printed object and build surface that maximizes the chances your object will be held in place for the duration of the print and then allow for clean and easy removal of the object from the build surface.

- PEI can easily be resized to your specific heated build plate by cutting with a sharp razor blade.

Buy 0.15mm PEI (polyetherimide) sheets from #Spool3D for your 3D printer in Canada without the surprise cost of the exchange rate!

6 Reviews

-

Total junk

Total junk. I installed it on my Railcore II 300ZL. The first print stuck to it like crazy, so much that I had to force a sharpened spatula underneath. It tore a bit of the PEI sheet. I thought it was my fault, so I changed a bunch of things and methods (I did let it cool down completely initially, but I now tried to reheat it, didn't work. then I tried to raise the head a little so the layer wouldn't be squishing so much in the sheet (it was perfect on glass). No change, still stuck to it but was able to get it to remove with effort. Now on the 3rd print, I removed a print without even using the spatula. A piece of PEI stuck to the part. My opinion? Get a thicker PEI sheet than this. Not worth it. I have a 1.5mm thick one here that I will install and test.

-

PEI (Polyetherimide) Sheet

Great for PLA, ABS, but not so great for TPU ruined one of the two sheets.

-

Replaced old film

Have an old plate that has seen lots of use over 2years, sometimes try to pop of prints before fully cooked, causing cracks and delamination blisters. Great replacement solution.

-

Pei sheet

Works great. With abs to get part off spray bed with alcohol, let sit for a minute, part will pop right off. Same for you.

-

Pei bed sheet

Perfect fit and replacement for the bed on my prusa i3 mk2. Patience when putting this stuff on is key, you only get 1 shot to do it lol use a card or something as you go to press it

-

Is this the best print bed?

I've struggled getting the right combination for various materials that I print. Glass works fine for PLA and if I added glue, then PETG was fine, but ABS was terrible. With this bed, I can print all materials without glue and headaches. Parts stick hard. You may need to experiment with the use of brims. Depending on nozzle size, I needed to significantly reduce the brim (for big nozzles - like 1.0 mm) - I use no brim at all. No issues either.