Bambu Lab

- Product

- Qty in Cart

- Quantity

- Price

- Subtotal

-

Bambu Lab H2C High Flow Induction Hotend (Right)

Bambu Lab

$92.00Free shipping in Canada for qualifying orders over $140 before tax. Multi-Material Printing with Less Waste The Vortek System uses up to six interchangeable induction-heated hotends to achieve true multi-material printing with significantly reduced...$92.00 -

Bambu Lab H2C Induction Hotend (Right)

Bambu Lab

$52.00Free shipping in Canada for qualifying orders over $140 before tax. Multi-Material Printing with Less Waste The Vortek System uses up to six interchangeable induction-heated hotends to achieve true multi-material printing with significantly reduced...$52.00 -

Bambu Lab Hardened Steel Extruder Gear Assembly

Bambu Lab

$26.00Free shipping in Canada for orders over $140 before tax. (via Canada Post) The hardened steel extruder gear assembly is an internal component of the hardened steel extruder unit. It comprises a driven gear and an active gear that work together to...$26.00 -

Bambu Lab Hardened Steel Extruder Gear Assembly - A1 Series

Bambu Lab

$13.00Free shipping in Canada for orders over $140 before tax. (via Canada Post) The Hardened Steel Extruder Gear Assembly is an internal component of the Extruder Unit. It comprises a driven gear and an active gear that work together to feed filament...$13.00 -

Out of stock

Bambu Lab Hardened Steel Extruder Unit - X1 Series

Bambu Lab

$58.00Free shipping in Canada for orders over $140 before tax. (via Canada Post) The hardened steel extruder unit is equipped with double gears made of hardened steel, which provides increased extrusion force, prevents slippage, and enhances abrasion...$58.00 -

Out of stock

Bambu Lab Heat Bed Unit - A1

Bambu Lab

$95.00Free shipping in Canada for orders over $140 before tax. (via Canada Post) Replacement Heat Bed assembly for the Bambu Lab A1 Printer (post recall) Installation Learn more about the replacement of the heat bed unit for A1 on Bambu Lab...$95.00 -

Bambu Lab Heatbed Cable - A1 mini

Bambu Lab

$8.00Free shipping in Canada for qualifying orders over $140 before tax. Overview Connects the A1 mini hotbed to the Mainboard, which is used to power the hotbed and provide feedback on the temperature of the hotbed. Installation Learn more about the...$8.00 -

Bambu Lab Heatbed Nozzle Wiper - A1

Bambu Lab

$4.00Free shipping in Canada for orders over $140 before tax. (via Canada Post) The heatbed nozzle wiper is designed for cleaning the hot nozzle before starting a print job. The machine's heatbed comes with a built-in nozzle wiping kit, and the cleaning...$4.00 -

Bambu Lab Heatbed Nozzle Wiper - A1 mini

Bambu Lab

$8.00Free shipping in Canada for orders over $140 before tax. (via Canada Post) The heatbed nozzle wiper is designed for cleaning the hot nozzle before starting a print job. The machine's heated bed comes with a built-in nozzle wiping kit, and the...$8.00 -

Bambu Lab Heatbed Sensor Unit

Bambu Lab

$7.00Free shipping in Canada for orders over $140 before tax. (via Canada Post) The heatbed sensor unit is a piezoelectric ceramic with a bracket installed, and is used to detect the condition of the surface pressure on the heatbed. There are 3 sensors...$7.00 -

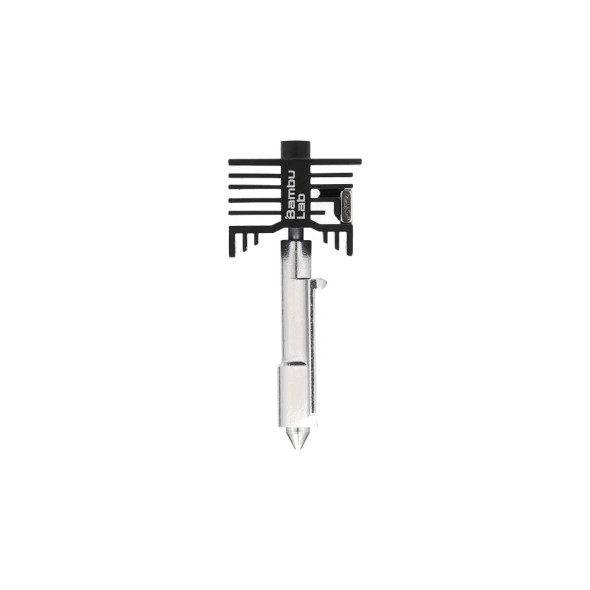

Bambu Lab Heating Assembly - H2D

Bambu Lab

$42.00Free shipping in Canada for qualifying orders over $140 before tax. The Hotend Heating Assembly is designed to heat the hotend and enable quick hotend replacement. The heating assembly secures the hotend with a clamping mechanism, allowing easy removal...$42.00 -

Bambu Lab High Flow Hotend - H2 Series & P2S

Bambu Lab

$70.00Free shipping in Canada for qualifying orders over $140 before tax. Save Up to 30% of Your Time High-Speed Precision Quick Swap Nozzle Design Real High Flow: Save Up to 30% of Your Time The Bambu High Flow Nozzle's optimized melt zone...$70.00

Bambu Lab 3D Printer Spare Parts: Find What You Need Fast

Bambu Lab is an innovative company in the 3D printing industry, renowned for developing high-performance 3D printers and related technologies that aim to push the boundaries of what's possible in additive manufacturing. The company focuses on integrating advanced technology with user-friendly design to meet the needs of both professional and hobbyist 3D printing communities. Here’s an overview of Bambu Lab, including its key products, technology, and contributions to the field of 3D printing:

Overview of Bambu Lab

Company Mission:

Bambu Lab’s mission is to advance 3D printing technology through innovation and precision, delivering high-quality, reliable, and easy-to-use 3D printers that cater to a wide range of applications. The company aims to bridge the gap between professional-grade equipment and consumer accessibility.

Focus Areas:

Innovation: Bambu Lab is dedicated to developing cutting-edge technologies that enhance the performance and versatility of 3D printers.

Quality: Emphasis is placed on creating robust and reliable 3D printers that meet the highest standards of manufacturing.

User Experience: The company designs its products with the end-user in mind, ensuring ease of use, accessibility, and exceptional print quality.

Key Products and Technologies

Bambu Lab X1 Carbon:

High-Performance 3D Printer: The X1 Carbon is one of Bambu Lab’s flagship models, featuring advanced technology and high precision. It includes features such as a high-speed corexy motion system, automatic bed leveling, and an integrated camera for remote monitoring.

Materials Compatibility: This printer is designed to handle a wide range of materials, including standard filaments, high-performance composites, and engineering-grade materials.

Advanced Features: The X1 Carbon incorporates Bambu Lab’s innovative AMS (Auto Material System), which automates material loading and switching, improving efficiency and ease of use.

Bambu Lab AMS (Auto Material System):

Automated Material Handling: The AMS system is designed to automate the process of material loading and switching, making it easier to work with multiple filaments and ensuring a more seamless printing experience.

Material Management: It helps manage various types of filaments, including those with different characteristics, ensuring consistent print quality and reducing the need for manual intervention.

Technology and Innovations

CoreXY Motion System:

Precision and Speed: Bambu Lab’s printers often utilize a CoreXY motion system, which is known for its precision and speed. This system enhances the accuracy of prints and allows for faster printing speeds.

Advanced Calibration:

Automatic Bed Leveling: Bambu Lab printers are equipped with advanced calibration systems, including automatic bed leveling, which ensures that the print surface is perfectly aligned for optimal results.

High-Temperature Printing:

Engineering Materials: The company’s printers are capable of high-temperature printing, allowing users to work with engineering-grade materials and composite filaments that require elevated extrusion temperatures.

User-Friendly Software:

Proprietary Software: Bambu Lab provides proprietary software that integrates with their hardware, offering features like advanced slicing options, remote control, and real-time monitoring to enhance the user experience.

Contributions to the 3D Printing Industry

Advancing 3D Printing Capabilities:

Innovation Leadership: Bambu Lab contributes to the advancement of 3D printing technology by introducing innovative features and systems that improve performance, usability, and print quality.

Expanding Accessibility:

User-Friendly Design: By focusing on ease of use and incorporating automated systems, Bambu Lab makes high-performance 3D printing more accessible to both professionals and enthusiasts.

Material Diversity:

Supporting Various Filaments: Bambu Lab’s printers are designed to support a wide range of materials, including standard and specialty filaments, expanding the possibilities for 3D printing applications.

Bambu Lab is a forward-thinking company that has made significant strides in the 3D printing industry by combining innovative technology with user-centric design. Through its advanced products like the X1 Carbon and AMS system, Bambu Lab enhances the capabilities and accessibility of 3D printing, making it easier for users to achieve high-quality results with a diverse range of materials. With a commitment to precision, reliability, and ease of use, Bambu Lab continues to be a key player in shaping the future of additive manufacturing.